Why Do People Preserve Food?

Food preservation has been a mainstay of self-sufficiency and survival from almost the beginning. Early on, folks would have times of plenty and times of scarcity. The need to stretch the times of plenty through the times of scarcity was the catalyst to early man finding and perfecting food preservation methods. As years went on and technology improved, these methods adapted to the ones commonly used today.

Folks these days – whether they are farmers, suburban homesteaders, or simply preparedness minded individuals – preserve their food for a variety of reasons. First and foremost, we still fight that mentality of stretching the bounty into the thin times. Many people also like to know exactly what they are eating and how it was handled. They can ensure this process more easily by growing and preserving their own food.

Major Causes Of Food Spoilage

Why do we need to preserve food? Unfortunately, food has a pretty short shelf-life and begins to degrade almost instantaneously from the moment it is harvest or slaughtered. The spoilage results from multiple things including physical damage, chemical damage and/or microbial growth.

Physical Damage

Physical damage can run the gambit in terms of what it includes. It is most usually revolves around punctures, bruising or damage caused by insects or other animals. This damage can cause water loss from the product and also provide places for microorganisms to start breeding.

Chemical Changes

Enzymes

Enzymes are chemicals that all plants and animals have. They help them grow, function and mature. Unfortunately, the enzymes in plants continue to work even after harvest and will change flavor and texture if not stopped. Enzymes don’t like heat, so blanching them (exposing them to boiling water or stream for a specified time) tends to do the trick here.

Oxidation

The presence of oxygen can cause a chemical change in food in much the same way it causes rust to appear on lead. If left unchecked, the oxidation process can cause food to go rancid. Heat will exacerbate this situation. Likewise, cold temps can slow down the process but will not stop it completely, even in a freezing environment. The oxidation process is one of the prime reason vacuum-sealed containers are used for long-term storage.

Microbial Growth

The three main types of microorganisms that can cause food to go bad are mold, yeast and bacteria:

Molds

Have you ever seen a piece of bread with a fuzzy bluish-green bump suddenly on it? Well then, you’ve seen mold. Mold is a non-discriminating spoilage method. It will destroy acid foods like fruits and tomatoes as easily as it will spoil low acid foods like meat and vegetables. Moisture, or the lack there of, seem to be no match for it. The only thing that will sufficiently kill mold is heating the food to the range of 140oF to 190oF.

Yeast

Much like molds, yeast is an equal opportunity food spoiler for both high and low acid foods. You’ll know your food was spoiled by yeast if it is slimy or bubbly. Much like mold, it can be eradicated when exposed to temperatures in the 140oF to 190oF range.

Bacteria

Bacteria is the rabbit equivalent of food spoilage. It can multiply rapidly in food and can grow in almost any condition. It does, however, prefer a warm, moist environment. It can be killed by heating but some spores require a temperature higher than that of boiling water, hence the need to pressure can some foods.

Types Of Food Preservation

There are quite a few different types of food preservation methods with the most common being canning, freezing and drying. Each method is chosen based upon what food you are preserving. Not all methods work for all food – for example, not all food can be canned. However, any food can be frozen safely. Whether the quality of the food suffers after it is frozen is up for debate and will be discussed in a later article. Picking the right type of food preservation methodology will both keep your food safe and provide good quality when you are ready to use it.

That being said, here’s a little more info on different food preservation methods:

Canning (High Acid Foods)

Boiling water canners work great for goods with a high natural acidity. Fruits and tomatoes with acid added to them (via lemon juice, citric acid or vinegar) fall into this category. The heat involved in this process will destroy the yeasts and molds that may be present while also forcing oxygen from the jars. The end result is a tight vacuum-sealed container which cannot be contaminated.

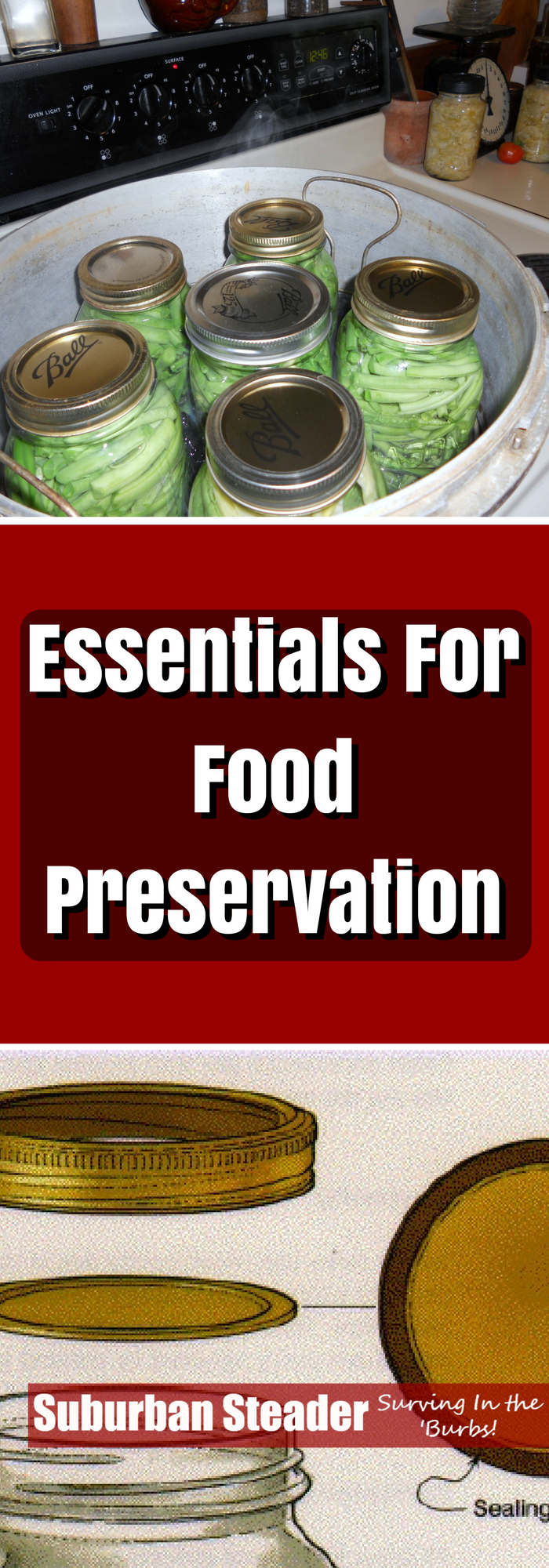

Canning (Low Acid Foods)

Low acid foods such as vegetables and meats must be canned in a pressure cooker. Much like in canning high acid foods, the heat from this process will destroy any yeast, mold, bacteria or bacteria spores that are present. You will also get tight vacuum-sealed containers from this process.

Pickling

Raising the acidity in food is known as pickling. You can raise the acidity by adding vinegar to the food or allowing it to ferment. Apple cider vinegar or distilled white vinegar can both be used in pickling and are selected based upon the taste profile you are trying to achieve. After pickling, you are able to can the food in a boiling water canner for long-term storage.

Jellied Fruit Products

Microbial growth is limited in jellied fruit products by the acid in the fruit. Sugar and/or pectin is added to bind up water in the fruit which removes any chance of a microbe to continue living. After that, yeast and mold are destroyed by heating the jellied fruit in a boiling water canner and vacuum-sealing the container.

Freezing

Plain and simple, freezing reduces the temperature of the food so low that microbial life cannot exist. The water in the food is frozen and, thus, the microbes cannot live. Freezing can also have detrimental effects as well. Because the water in the food is frozen, it expands and can cause some physical to damage to food over time.

Drying

Drying simply removes the moisture from the food which prevents any microbial growth to occur.

Wrap-Up

I hope you enjoyed this introduction to food preservation. There is, obviously, a lot of information to cover on this topic and I will be doing my best to get it out to you. Keep an eye out for our next article where we will got more in-depth into the canning process.

And, as always, if you have any questions, please feel free to ask them in the comments below or on Facebook.

Two-Piece Closures – Home canners typically use a two-piece closure system which consists of a metal lid and a metal band. The metal lid has a rubber-like sealing compound that interfaces with the jar lid. The metal band is tightened to hold the metal lid in place. Lids are a “one and done” item meaning they are only used once. Bands can be used over and over again assuming they are washed and dried between uses.

Two-Piece Closures – Home canners typically use a two-piece closure system which consists of a metal lid and a metal band. The metal lid has a rubber-like sealing compound that interfaces with the jar lid. The metal band is tightened to hold the metal lid in place. Lids are a “one and done” item meaning they are only used once. Bands can be used over and over again assuming they are washed and dried between uses.